Technology

The Technology of Electronic Breakout Boxes and Their Applications in Modern Technology

Introduction to Electronic Breakout Boxes

Electronic breakout boxes are essential tools in the realm of modern technology, serving as pivotal devices that facilitate the interfacing of different electronic components and systems. Essentially, an electronic breakout box is a piece of hardware designed to break out multi-conductor cables into separate, manageable connections, making it easier to test and troubleshoot complex systems. These boxes are integral in simplifying the connectivity between various electronic circuits and devices, ensuring seamless communication and operational efficiency.

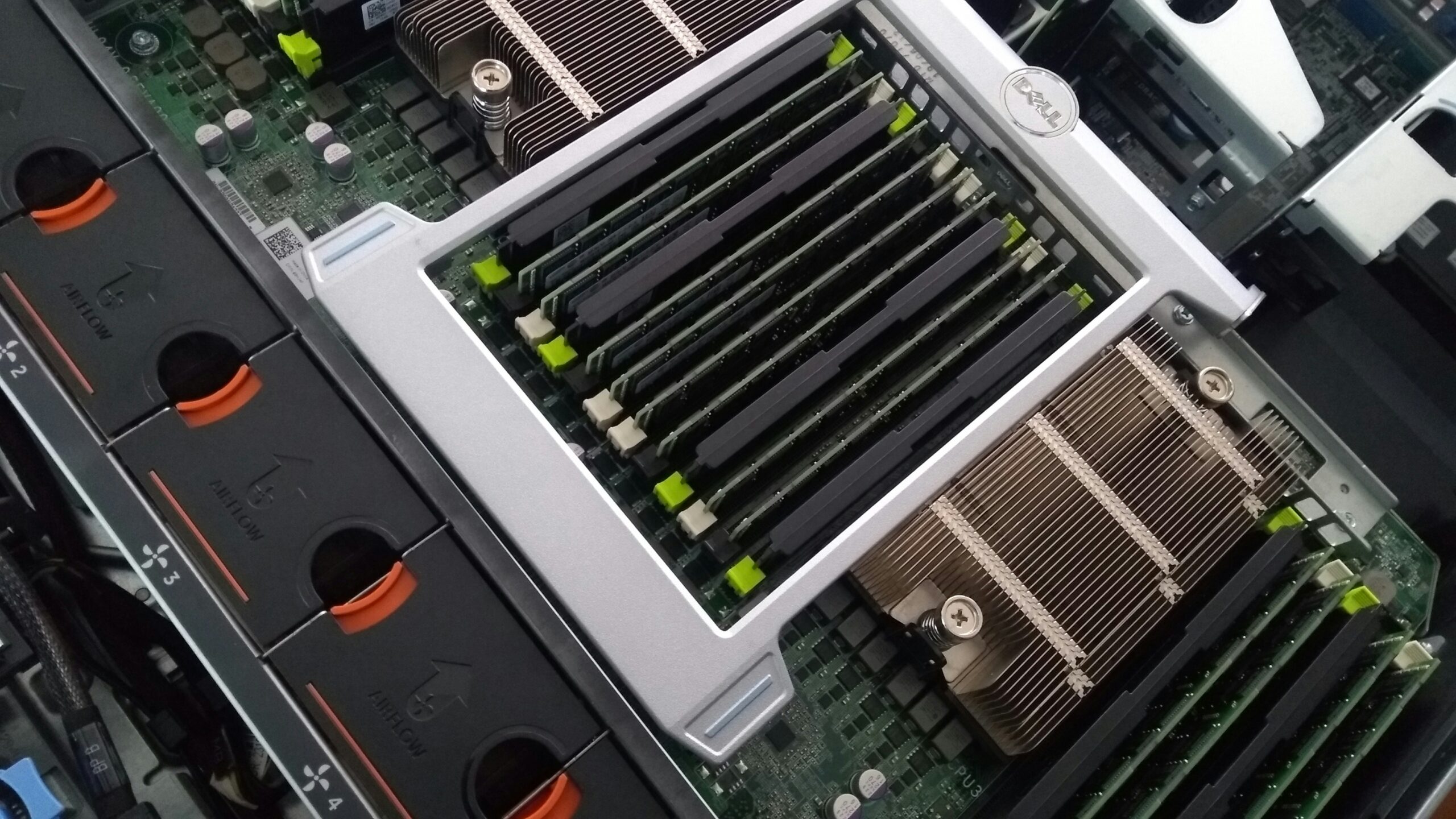

The fundamental architecture of an electronic breakout box typically includes a series of input and output connectors, signal conditioning circuits, and sometimes microcontrollers or other processing units. These components work together to route signals between different parts of a system, allowing for detailed monitoring and control. Unlike traditional breakout boxes, which may only provide basic connectivity, electronic breakout boxes often incorporate advanced features such as signal amplification, filtering, and conversion, enhancing their functionality and versatility.

Historically, the concept of breakout boxes dates back to the early days of electronic development when engineers needed a practical solution for managing complex wiring configurations. Over the years, as electronic systems have become more sophisticated, the design and capabilities of breakout boxes have evolved significantly. Modern electronic breakout boxes now offer a range of advanced features, including digital interfaces, programmable settings, and integration with software tools, reflecting the rapid advancements in technology.

Key terms to understand when delving into the world of electronic breakout boxes include “signal routing,” “connectivity,” “multi-conductor cables,” and “signal conditioning.” These concepts are crucial for grasping how breakout boxes function and their role in modern electronic systems. By providing a reliable and efficient means of managing connections and signals, electronic breakout boxes play a vital role in the development, testing, and maintenance of contemporary technological applications.

Technological Components and Functionality

Electronic breakout boxes are complex devices composed of various intricate technological components, each playing a crucial role in their overall functionality. At the heart of these devices are microcontrollers, which serve as the central processing units that manage the data flow and execute commands. Microcontrollers in breakout boxes are designed to handle various interfacing tasks, including signal conditioning, data conversion, and communication with other electronic systems.

Connectors form another essential component of electronic breakout boxes. These connectors are the physical interfaces that allow the breakout boxes to link with other electronic devices. They come in various forms, such as pin headers, screw terminals, and specialized sockets, to accommodate different types of signals and voltages. These connectors ensure that the breakout boxes can be easily integrated into diverse testing and debugging environments.

Interface boards are integral to the functionality of breakout boxes, serving as the intermediary between the microcontroller and the connectors. These boards are designed to support multiple communication protocols, such as I2C, SPI, and UART, enabling seamless data exchange between the breakout box and the connected devices. The interface boards also include various circuitry components like resistors, capacitors, and diodes that help in signal conditioning and protection.

There are different types of breakout boxes available, each tailored to specific testing and debugging needs. Analog breakout boxes are designed to handle analog signals, offering features like signal amplification and filtering. Digital breakout boxes, on the other hand, are optimized for digital signals and often include features like logic analyzers and digital pattern generators. Hybrid models combine the functionalities of both analog and digital breakout boxes, providing a versatile solution for complex electronic systems.

The synergy between these components—microcontrollers, connectors, and interface boards—enables electronic breakout boxes to facilitate efficient testing, debugging, and connectivity. Their modular design and versatile functionality make them indispensable tools in modern technology, catering to a wide range of applications and industries.

Applications of Electronic Breakout Boxes in Various Industries

Electronic breakout boxes have become indispensable tools across a multitude of industries, playing a critical role in prototyping, signal testing, and troubleshooting. Their versatile nature allows for a wide range of applications, enhancing efficiency and precision in complex electronic systems.

Automotive Industry

In the automotive sector, electronic breakout boxes are vital for testing and debugging vehicle electronics. They are extensively used in the development of new vehicle models and in diagnostic applications. For instance, during the prototyping phase, engineers use breakout boxes to isolate and test specific components of the vehicle’s electronic control unit (ECU). This facilitates early detection of faults and ensures robust performance. A case study involving Tesla highlighted how breakout boxes were instrumental in refining the Model S’s electronic systems, leading to significant improvements in its Autopilot functionality.

Aerospace Industry

The aerospace industry relies heavily on electronic breakout boxes for ensuring the reliability and safety of aircraft systems. These devices enable engineers to conduct thorough signal testing and troubleshoot avionics, which are critical for flight safety. During the assembly of an aircraft, breakout boxes are used to verify connections and functionality of flight control systems. For example, Boeing utilized breakout boxes to streamline the development of the 787 Dreamliner, ensuring that complex electronic systems interfaced correctly, thereby reducing the risk of in-flight malfunctions.

Telecommunications Industry

Telecommunications companies employ electronic breakout boxes to manage and test complex network infrastructures. These tools are essential for signal integrity testing and troubleshooting network issues. In the deployment of 5G networks, for example, breakout boxes allow engineers to isolate and test individual components of the network, ensuring optimal performance and reliability. A notable instance is Verizon’s use of breakout boxes in their 5G rollout, which helped in identifying and resolving signal interference issues, thereby enhancing the overall network performance.

Consumer Electronics Industry

In the consumer electronics sector, electronic breakout boxes are crucial for the development and testing of new products. They facilitate the quick identification of faults and allow for rapid prototyping. During the development of a new smartphone, for instance, breakout boxes are used to test individual components such as the display, battery, and sensors. Apple’s engineering team utilized breakout boxes extensively in the development of the iPhone 12, enabling them to fine-tune the device’s performance and ensure high quality before market release.

Through these examples, it is clear that electronic breakout boxes provide significant practical benefits in various industries. Their ability to enhance prototyping, signal testing, and troubleshooting processes makes them an essential tool in modern technology development.

Future Trends and Innovations in Breakout Box Technology

As we venture into the future, electronic breakout boxes are poised to undergo significant transformations driven by advancements in miniaturization, wireless connectivity, and integration with artificial intelligence (AI) and machine learning. These innovations promise to enhance the diagnostic capabilities and overall functionality of breakout boxes, making them indispensable tools in various technological applications.

Miniaturization is a key trend that is expected to revolutionize breakout box technology. With continuous improvements in semiconductor technology and circuit design, future breakout boxes will likely become more compact and portable without compromising performance. This will facilitate their use in a broader range of environments, from industrial settings to field operations.

Wireless connectivity is another area where substantial progress is anticipated. The integration of advanced wireless technologies will eliminate the need for cumbersome cables, enhancing the ease of use and flexibility of breakout boxes. This will be particularly beneficial in dynamic and remote environments where wired connections are impractical. The advent of 5G technology will further bolster this trend, providing high-speed, low-latency connections that will enable real-time data transmission and remote diagnostics.

AI and machine learning are set to play a crucial role in the future of breakout boxes. By incorporating these technologies, breakout boxes will be able to perform more sophisticated analyses, identify patterns, and predict potential issues before they occur. This predictive maintenance capability will be invaluable in sectors such as manufacturing, automotive, and aerospace, where early detection of faults can prevent costly downtimes and enhance operational efficiency.

The influence of the Internet of Things (IoT) cannot be overstated. As breakout boxes become more interconnected with IoT devices, they will provide more comprehensive diagnostic insights and enable seamless integration with other smart systems. This interconnectedness will pave the way for more intelligent and automated workflows, further increasing the utility of breakout boxes in modern technology.

Industry experts predict that ongoing research and development efforts will continue to push the boundaries of what breakout boxes can achieve. Innovations in sensor technology, enhanced user interfaces, and improved data processing capabilities are just a few areas where significant advancements are expected. These developments will ensure that breakout boxes remain at the forefront of diagnostic technology, adapting to meet the evolving needs of various industries.